TOPIC

Comprehensive Guide to Cleanroom Certification and Testing

Cleanroom certification and testing ensure controlled environments meet stringent air quality, particle count, and safety standards. The process includes airflow analysis, HEPA filter integrity tests, and environmental monitoring. Regular certification complies with industry regulations, ensuring optimal conditions for sensitive pharmaceuticals, electronics, and biotechnology processes.

What Is Cleanroom Certification?

Cleanroom certification is a rigorous process that ensures controlled environments, or cleanrooms, meet strict standards and regulations for air quality, particle count, and other environmental conditions crucial for industries like pharmaceuticals, electronics, and biotechnology.

Achieving cleanroom certification CA guarantees that facilities operate within internationally recognized standards, which is crucial in minimizing risks associated with contamination. The process involves extensive testing and evaluation to ensure the cleanroom environment meets these standards. This certification is essential for preserving the integrity and caliber of goods produced in these settings and guaranteeing that they are free of impurities that might jeopardize their usability or safety.

The Importance of Cleanroom Certification

Cleanroom certification ensures product quality, regulatory compliance, and personnel health and safety. It reduces contamination, especially in sensitive industries like pharmaceuticals and biotechnology. The CDC guidelines emphasize the importance of maintaining a sterile environment for patient safety in healthcare settings. Regular audits and certifications ensure facilities are regularly reviewed and updated to meet standards. This not only maintains product integrity but also enhances operational efficiency. The process maintains product integrity and elevates an organization’s reputation as a reliable and quality-conscious entity.

Standard Tests in Cleanroom Certification

Airborne Particle Counts and HEPA Filter Integrity Testing are crucial for maintaining cleanroom cleanliness. Airborne Particle Counts measure the number and size of particles in the air, ensuring the cleanroom meets the required cleanliness level. HEPA Filter Integrity Testing verifies the functioning of HEPA filters, ensuring they effectively remove contaminants. Airflow and Segregation Tests ensure airflow patterns are designed to prevent cross-contamination. Pressure Differential Monitoring maintains the correct pressure differential between cleanroom zones, preventing contamination inflow from less clean areas. Temperature and Humidity Control tests ensure the cleanroom’s environmental conditions are within specified ranges, ensuring product quality and personnel comfort. Regularly performing these tests helps maintain the cleanroom’s integrity and compliance with relevant standards.

Steps to Obtain Cleanroom Certification

Obtaining cleanroom certification involves a thorough review of existing conditions, preparation of necessary documentation and standard operating procedures (SOPs), testing, review, and audit by an independent auditor, and certification by an accredited body. The initial assessment phase identifies gaps and areas for improvement, while the documentation phase outlines protocols for maintaining the cleanroom environment in line with industry standards. Regular audits and reviews help address gaps, ensuring continuous improvement and compliance. The certification phase confirms that the cleanroom adheres to all necessary standards, providing confidence to the facility and its clients. This comprehensive approach ensures the cleanroom meets all the required standards and effectively performs under regulated conditions.

Best Practices in Maintaining Cleanrooms

Maintaining a certified cleanroom requires strict protocols, including regular cleaning schedules, proper gowning, routine equipment checks, and continuous monitoring of environmental conditions. These practices ensure the removal of contaminants, minimize contamination introduction, and ensure critical systems like air filtration are correctly functioning. Staying updated with CDC guidelines helps maintain sterility and reduce contamination risks. Fostering a disciplined culture among personnel is crucial, and regular training on cleanroom protocols is essential. Routine inspections and surprise audits encourage strict adherence to procedures, ensuring cleanrooms operate at high levels of cleanliness and efficiency.

Frequently Asked Questions

Here are some common questions about cleanroom certification and testing:

- Q: How often should cleanroom certification be renewed?

- A: Typically, cleanroom certification must be renewed annually or as regulatory bodies specify. Regular renewal ensures that the cleanroom continues to meet evolving standards and remains in compliance with industry regulations.

- Q: What industries require cleanroom certification?

- A: Industries such as pharmaceuticals, healthcare, electronics manufacturing, and biotechnology commonly require cleanroom certification due to the high sensitivity and precision required in their operations.

- Q: Can cleanroom standards vary by region?

- A: Yes, cleanroom standards can vary by country and industry regulations. Organizations must stay informed about regional standards and ensure their cleanrooms adhere to local and international laws.

Expert Tips for Cleanroom Management

Experts suggest that maintaining optimal cleanroom performance involves the following:

- Continuous staff training.

- We are using advanced monitoring systems to track environmental parameters.

- We are establishing a robust preventative maintenance schedule.

Engaging third-party auditors can provide valuable insights and recommendations for improvement, identifying areas that may have been overlooked internally. These audits can help organizations achieve higher certification and operational excellence levels, ensuring their cleanrooms remain efficient and compliant. By following these expert tips, organizations can achieve higher certification and operational excellence levels, ensuring their cleanrooms stay efficient and compliant.

Final Thoughts

Cleanroom certification is crucial for maintaining high standards in various industries. It entails thorough testing and assessment to ensure cleanrooms fulfill the requirements and improve product quality and safety. Resources like the CDC Guidelines on Environmental Infection Control offer valuable insights into maintaining sterile and controlled environments, ensuring the safety and quality of cleanroom environments.

TOPIC

How Aerospace Fittings Drive Safety and Innovation in Modern Aviation

Introduction to Aerospace Fittings

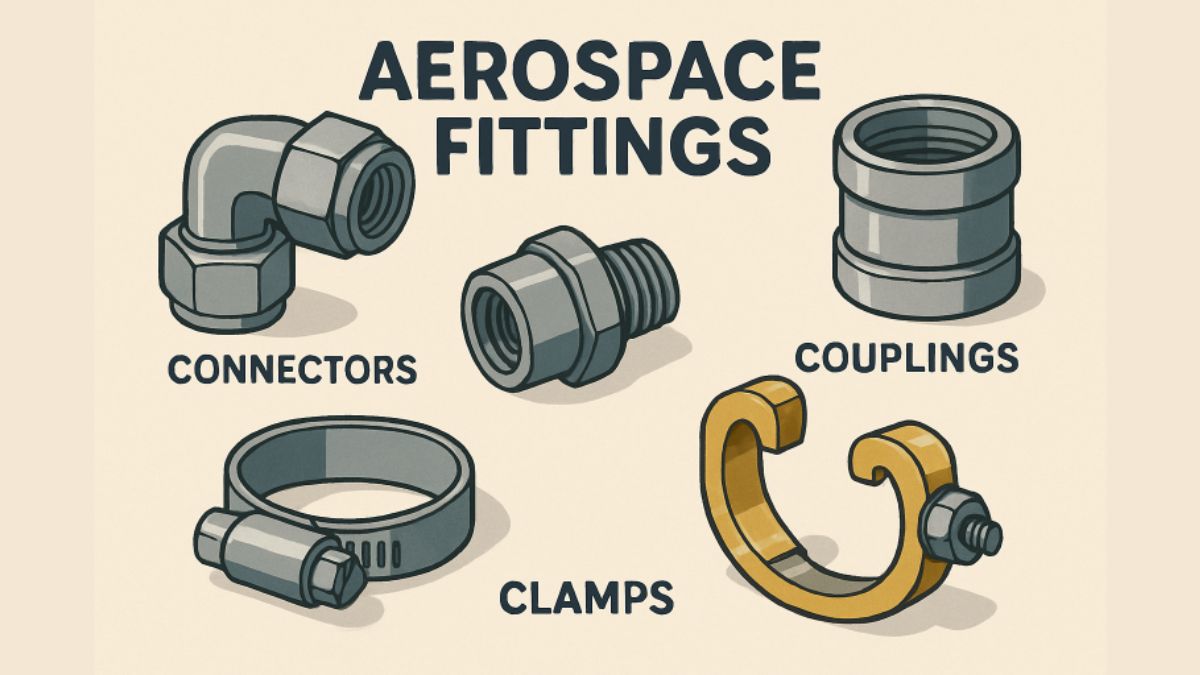

Examining the intricacies of aviation safety and performance reveals that essential components are not always those in the public eye. While engines and airframes often command attention, even less conspicuous parts such as aerospace fittings fundamentally uphold an aircraft’s safety and operational reliability. These connectors, couplings, and clamps work behind the scenes, ensuring that hydraulics, fuel, and avionics remain stable under the demanding forces encountered during flight.

Consistent, uncompromising quality in aerospace fittings isn’t an afterthought—it’s a cornerstone of modern aircraft design. Chemistry, physics, and engineering precision all converge to develop fittings that can withstand rapid pressure changes, vibration, and temperature extremes. Whether for engineers overseeing design or aviation enthusiasts eager to deepen their technical appreciation, understanding these components is central to truly grasping what keeps aircraft safely aloft.

Why Fittings Matter: The Unsung Heroes

The harsh realities of flight—extreme altitudes, fluctuating temperatures, and continual vibration—impose tremendous stress on every part of an aircraft. Though they may appear small, Fittings are lynchpins that keep systems sealed, aligned, and operational. Their failure can have catastrophic effects, as shown in accident investigations where even minor leaks have compromised entire systems. Reinforcing the importance of rigorous fitting standards, a recent industry report emphasized that robust, high-integrity fitting systems are directly linked to reducing system-wide failures and enhancing long-term safety.

Critical Qualities of Aerospace Fittings

Each fitting is engineered with a precise set of qualities in mind. The industry demands manufacturing that utilizes high-grade alloys—like stainless steel, titanium, and sometimes specialty composites—to combat corrosion, fatigue, and thermal expansion. Adherence to global standards, such as those mandated by the SAE and ASTM, is not optional but required. Diverse fitting types—flare, flareless, quick-disconnect—are specified according to each application’s pressure, vibration, and fluid compatibility requirements, reinforcing the necessity for exact engineering and rigorous certification protocols.

Challenges in Maintenance and Replacement

The maintenance of aircraft fittings extends well beyond the adjustment of a wrench. Proper upkeep requires a proactive approach, including scheduled inspections for signs of wear, corrosion, or distortion using advanced methods like dye-penetrant and ultrasonic testing. Maintenance professionals must heed detailed specifications for installation torque and never substitute components with unauthorized alternatives. Recent technical updates from authoritative sources, such as the Federal Aviation Administration, have verified the dangers of shortcutting these processes, ensuring that only qualified and traceable parts are used during overhauls.

Materials and Innovation in Fitting Design

Material science drives continual evolution in the design and application of aircraft fittings. Increasingly, titanium alloys, which marry high strength with low weight, are selected for their superior resistance to fatigue and corrosion. Advanced composite materials and introducing specialized coatings—such as ceramic or nano-structured films—further reinforce performance, protecting fittings from the aggressive effects of temperature changes and corrosive fluids. This innovation cycle promotes safety and helps realize emission reduction goals by supporting lighter and more fuel-efficient aircraft.

Compliance, Traceability, and Data Management

Complete traceability is non-negotiable in aerospace. Each fitting must be documented through a rigorous digital tracking system, from its raw material origin to its eventual installation on an airframe. These quality control processes are strong deterrents against counterfeit or defective components entering the supply chain and facilitate rapid recall or investigation if an incident arises. Leading aerospace manufacturers collaborate closely with aviation authorities to ensure compliance with evolving global standards and audit protocols.

New Demands: Emerging Fuels and Sustainability

The aviation industry’s commitment to reducing its environmental impact drives significant changes in fuel systems and compatible fittings. As aircraft adapt to biofuels, hydrogen, and other alternative energy sources, fittings must be reimagined to handle new chemical compositions and performance demands. This evolution pushes the boundaries of engineering innovation and material compatibility, challenging manufacturers and regulators to collaborate closely on safe, sustainable solutions. Ongoing research, documented extensively in publications like Scientific American, highlights the need for robust and adaptive fitting designs as alternative fuel adoption accelerates.

Looking Ahead: The Future of Fittings in a Changing Industry

Aviation is entering an era of digitalization, new materials, and an unprecedented focus on safety and environmental responsibility. The role of fittings, though humble, will only increase as the complexity of aircraft systems grows and new regulatory mandates take effect worldwide. By prioritizing innovation, exacting technical standards, and ongoing education, stakeholders across the aviation supply chain can ensure fittings continue to underpin flight safety and sustainability. Staying informed through trusted news outlets and industry resources guarantees preparedness for the next generation of challenges and advances in aviation technology.

TOPIC

Choosing The Right Residential Generator For Your Home

Power outages are becoming increasingly common, leaving many homeowners searching for reliable backup solutions. Investing in a residential generator offers not only continuity of essential services like heating, refrigeration, and security, but also the peace of mind that your home is protected when the grid goes down. Understanding how to choose the best generator for your specific needs can be a challenge, so it’s crucial to examine options, features, and installation considerations before making a purchase.

Whether preparing for storm season or planning for unexpected outages, evaluating home generators Great Falls VA will lead you to modern models with advanced features and safe installation services tailored to local requirements. The right selection will ensure your family’s comfort and safety without overextending your budget or energy resources. Choosing the right generator involves selecting the right fuel type and capacity and considering its impact on household energy bills. Today’s units are more efficient and environmentally friendly. Consulting experts and planning carefully, following local regulations for proper maintenance, and understanding lifecycle costs are crucial for long-term savings.

Understanding Your Home’s Power Needs

Calculating wattage is essential for assessing your household’s power needs before buying a generator. It helps determine the total wattage of appliances, lighting, and systems to ensure the generator supports your needs during outages. Overestimating can cause unnecessary costs. Wattage calculators or a qualified electrician can refine your needs. Prioritizing essential circuits like refrigerators, medical equipment, lighting, sump pumps, and heating/cooling makes your generator more compact and cost-effective.

Different Types of Residential Generators

Portable generators are affordable, flexible, and easy to store, making them ideal for powering a few key devices. Standby generators are installed outside the home and can power the entire house automatically during an outage. They have lower upfront costs, limited capacity, and may not power hardwired systems. On the other hand, standby generators automatically restore power, have higher output, and require more investment and professional installation.

Fuel Choices: What’s Best For You?

Generators are typically powered by gasoline, propane, or natural gas. Gasoline is common for portable models but requires regular rotation. Propane offers a cleaner burn and is suitable for intermittent use. Natural gas is preferred for standby systems due to its reliability and connection to a continuous municipal supply. Each fuel type has its cost and environmental implications. Natural gas and propane are cleaner-burning and produce fewer emissions, but may be the only option in rural areas or during fuel shortages. Balancing convenience, cost, and environmental impact is crucial for long-term satisfaction.

Installation: DIY or Professional?

Local building and electrical codes often regulate generator installation, requiring permits and licensed professionals to install standby systems. Adherence to code is crucial for safety and insurance liability. Most generator manufacturers require professional installation to validate warranties, ensuring proper placement, secure connections, and compliance with local ordinances. Incorrect DIY installation can void warranties, pose fire risks, and cause carbon monoxide hazards.

Key Features To Look For

Automatic standby generators detect outages with sensors to start quickly, unlike manual-start models that need presence, which isn’t always feasible during emergencies. Transfer switches connect the generator to the home, preventing backfeeding and protecting utility workers. Some units feature Wi-Fi monitoring. Noise and emission ratings matter, especially near neighbors or in regulated neighborhoods. Choose low-emission, EPA-certified engines and consider your household’s needs when selecting a generator.

Routine Maintenance and Troubleshooting

Regular preventative maintenance, such as oil changes, fuel stabilizer use, battery testing, air filter replacement, and exercise runs, extends the life and reliability of your generator. Follow the manufacturer’s instructions for servicing intervals. Check for dead batteries, old fuel, clogged filters, or tripped circuit breakers if your generator won’t start. Keep your maintenance log updated to diagnose and prevent future problems.

Cost, Warranty, and Long-Term Value

Standby generators can increase home value and protect lost food, frozen pipes, or missed work, while portable generators offer short-term savings but may result in higher long-term maintenance and fuel costs. Reputable brands offer warranties ranging from 3 to 10 years, covering both parts and labor. Read the fine print and maintain maintenance records to ensure coverage.

Conclusion

Choosing the right home generator requires understanding your power needs, fuel options, installation, and maintenance. Balancing cost, capacity, and reliability ensures safety and function during outages. Professional guidance, upkeep, and warranties enhance long-term value. A good generator offers backup power and peace of mind, protecting your home and family.

TOPIC

How Pressure Washing Boosts Curb Appeal Instantly

Introduction

In today’s competitive real estate market, achieving striking curb appeal is more important than ever. The visual impression your home makes at first glance plays a pivotal role, whether you’re aiming to attract buyers or wish to create a welcoming atmosphere that fills you with pride. The appearance of your exterior spaces—from walkways to siding and outdoor living areas—often sets the tone for expectations before a guest, neighbor, or prospective buyer even crosses your threshold. Professional pressure washing is one of the fastest, most dramatic, and cost-effective methods to restore your home’s facade. By applying top-quality products and pressure lift Masport vacuum pump oil, homeowners can ensure their equipment performs optimally and that pristine results last for the long term.

Pressure washing far surpasses the cleaning power of regular hoses or manual scrubbing. With powerful, controlled jets of water, years of unsightly dirt, algae, mold, and environmental grime can be lifted away within moments, revealing the true beauty beneath on surfaces such as driveways, walkways, walls, and patios. This comprehensive guide unpacks why pressure washing is an optimal investment, offering instant visual transformation and lasting value to homeowners who want to make their homes stand out in any neighborhood.

Understanding Curb Appeal

Curb appeal encompasses your property’s overall visual attractiveness and charm as it appears from the street. It’s your first impression—an immediate assessment made by everyone, from prospective buyers to daily passersby. Well-maintained curb appeal typically correlates with increased home values, easier resale, and a sense of neighborhood pride. In the real estate world, that first impression can often decide whether potential buyers feel compelled to request a viewing or even place an offer.

Homes with high curb appeal often receive more foot traffic from buyers, attract higher offers, and can even sell faster than those in the same price range that show neglect. Conversely, an exterior marred by dirt, mildew, or faded surfaces may signal to buyers that the property, while possibly sound inside, isn’t cared for attentively. A clean, welcoming exterior reassures anyone approaching your door that your property is well-maintained, setting the stage for positive expectations before one ever sees the interior.

The Science Behind Pressure Washing

Pressure washing harnesses a straightforward yet exceptionally effective concept: water accelerated at high pressure is used to blast contaminants from surfaces. Unlike traditional cleaning that often requires backbreaking scrubbing and reliance on chemicals, pressure washing takes cleaning efficiency to a new level while drastically reducing physical effort and chemical runoff. With proper technique and the right equipment, pressure washing can completely transform grimy, weathered exteriors into inviting, radiant spaces within hours.

The technology behind pressure washing is particularly useful in eliminating persistent stuff like moss, algae, lichen, and years’ worth of built-up mold. Beyond restoring a home’s brilliant exterior, such power washing also helps preserve the integrity of building materials, preventing structural decay that develops if these growths are unchecked.

Benefits Over Traditional Cleaning

- Provides deep cleaning for areas that are difficult or impossible to reach by hand

- Significantly reduces the requirement for harsh or environmentally harmful chemicals

- Saves considerable amounts of time, energy, and even water compared to manual scrubbing methods

- Delivers consistent results, ensuring your entire exterior looks uniformly refreshed

Key Areas to Pressure Wash for Maximum Impact

Certain parts of your home’s exterior are especially prone to grime accumulation and should be prioritized during your pressure washing regimen for the best boost in curb appeal.

Driveways and Walkways

Driveways and walkways bear the brunt of daily use—stains from vehicles, foot traffic, and the constant bombardment of the elements can lead to discoloration, oil stains, rust, and deeply embedded dirt. Pressure washing these surfaces removes unsightly blemishes and instantly brightens the entire entryway, giving your property a polished and well-groomed appearance.

Exterior Walls and Siding

Siding, whether vinyl, wood, brick, or stucco, naturally collects dust, pollen, and the residue of rain and wind over time. This accumulation can dull exterior colors and may even grow mold and mildew. Regular pressure washing refreshes siding surfaces, keeps paint looking new, and can extend the lifespan of exterior finishes and paint jobs by removing these damaging contaminants before they cause lasting harm.

Decks and Patios

Outdoor living areas such as decks and patios can quickly become dirty, slippery, or stained due to algae, moss, and mildew growth, especially in shaded or damp areas. Pressure washing restores the look and safety of these spaces, reviving the color and texture of wood or composite decks and patios and preventing slipping hazards. Guests and family members alike will appreciate the clean, welcoming environment for gatherings and relaxation.

Fences and Gates

Fences help define property boundaries and frame the landscape, but they’re often overlooked. Whether wood or metal, fences face constant exposure to the elements and accumulate grime, old paint, and organic buildup. Pressure washing these areas helps strip away layers of dirt and oxidation, dramatically improving appearance, helping to prevent premature rot or rust, and prolonging the useful life of your fencing investment.

Safety Considerations and Best Practices

Pressure washing is highly effective—but only when used with knowledge and care. The force involved is powerful enough to cause unintended damage if settings are misapplied, especially on softer surfaces like wood, vinyl, or painted finishes. Here’s how to ensure safe and effective cleaning every time:

- Always check and select the correct pressure setting and nozzle for the cleaned material—higher isn’t always better.

- To prevent chemical or spray damage, protect surrounding plants and landscaping by covering or saturating them with water before washing.

- While operating a pressure washer, follow equipment instructions, use manufacturer-recommended products, and wear safety gear like gloves, boots, and protective glasses.

- If the job feels overwhelming or concerns for surface sensitivity arise, enlisting a professional service guarantees expert handling and optimal curb appeal improvements with no risk to your investment.

Conclusion

Pressure washing is a quick, cost-effective, and highly impactful way to enhance your home’s curb appeal. From reviving driveways and walkways to brightening decks, patios, and fences, it reveals the vibrant features that might otherwise be hidden beneath years of accumulation. Whether you’re preparing to sell or wish to enjoy a renewed sense of pride in your property, investing in pressure washing through professionals ensures dramatic, lasting improvements. Savvy homeowners know that a spotless exterior is more than just an aesthetic upgrade; it is a strategic move to maintain and increase property value for years to come.

-

TOPIC1 year ago

TOPIC1 year agoExploring Fappelo: The Rise of a Unique Online Community

-

TECHNOLOGY1 year ago

TECHNOLOGY1 year agoExploring the Impact of Shannon Swanick TPO on Modern Blogging

-

CRYPTO1 year ago

CRYPTO1 year agoUnderstanding the Landscape of Crypto30x.com regulation: What You Need to Know

-

TOPIC12 months ago

TOPIC12 months agoThe Art of Expression: Analyzing Puppygirlxd Most Iconic Creations

-

CRYPTO1 year ago

CRYPTO1 year agoExploring the Benefits of Using Biitland.com Stablecoins

-

HEALTH12 months ago

HEALTH12 months agoTop 5 Benefits of Using a Mansrufer for Your Daily Routine

-

BUSINESS1 year ago

BUSINESS1 year agoHow Legal Insights Can Streamline Business Operations

-

TOPIC1 year ago

TOPIC1 year agoTop 5 Myths About Hypackel Debunked!